Column internals

How does flue gas cleaning work? Key process parameters?

Flue gas cleaning is a mass transfer process with an objective to remove unwanted or hazardous substances from the process. Flue gas cleaning is used in a variety of industries and applications.

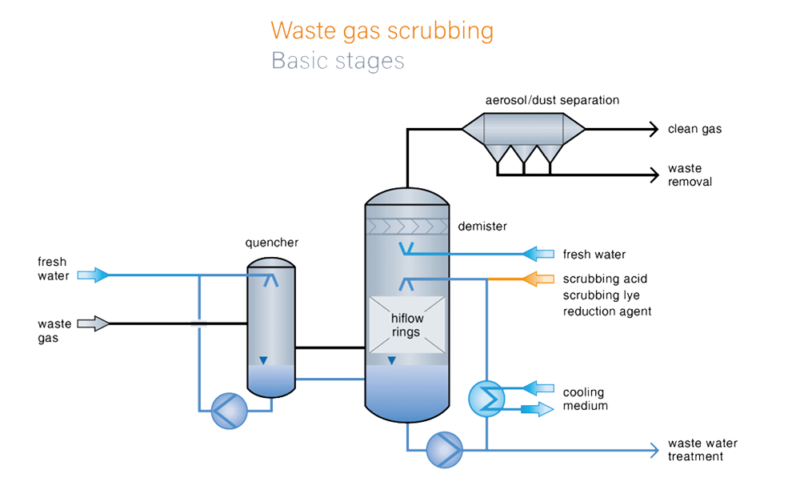

Before the hot process gas is introduced into the bottom of the scrubber column it often needs to be cooled to its dew point in a quench, using spray nozzles. The incoming gas then flows from the bottom of the column and out the at the top of the column. In the process, a scrubbing liquid is added in the opposite direction to the gas flow. The function of the scrubber fluid is to create mass transfer by absorption through contact with the impurities in the gas. The unwanted substances are transferred to the scrubber liquid. The liquid is then removed and purified. In some processes, chemical substances are added to the scrubber liquid to further improve the absorption process.

The larger the contact between gas and scrubber liquid, the more efficient the gas cleaning process. The gas-liquid contact is optimised by increasing the residence time in the column and maximising the surface area of the scrubber. This is achieved by using spray nozzles designed to create small droplets, increasing the total surface area of the mass transfer process. Random packings or structured packings are used to increase the residence time and the active contact area between gas and liquid.

Which process parameters are important when designing a scrubber for flue gas cleaning?

To optimise a mass transfer process, many parameters need to be taken into account, e.g:

- What is the purpose of the process and what do you want to achieve?

- Gas flow

- Gas composition

- Dimensional constraints

- Pressure and pressure drop

- Temperature

- Type of pollutant, its solubility and concentration

Each process is unique and various parameters often need to be weighed against each other to find the most optimal solution. To achieve the best possible result, it is important to have good knowledge about the various process components and their impact. At the same time, an overall perspective is required to find the most sustainable solution for the specific process.