EXAIR air knives

EXAIR air knives are designed to offer efficient, quiet solutions for cleaning, drying and cooling using compressed air. EXAIR air knives create a laminar airflow that is distributed with great force, evenly across the entire air knife, ensuring optimal performance even at high pressures.

Which air knife is best for your application?

Here is a comparison of EXAIR's three different types of air knives - Super Air Knife, Standard Air Knife and Full-Flow Air Knife.

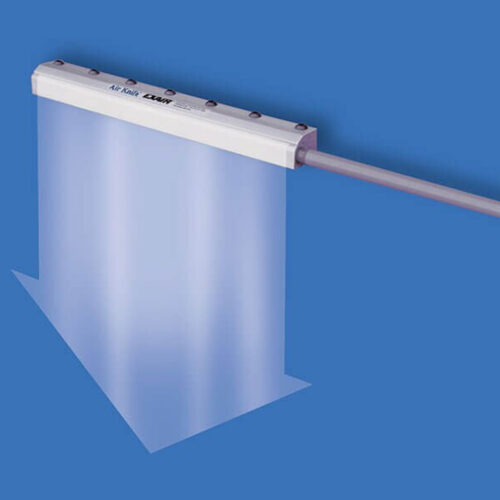

Super Air Knife

- Best choice for all types of applications

- Lowest operating cost

- Highest efficiency (lowest consumption of compressed air)

- Quietest

- Air gain ratio of 40:1

- Compressed air inlets on each end and at the bottom of the air knife

- Airflow length and total air knife length are the same

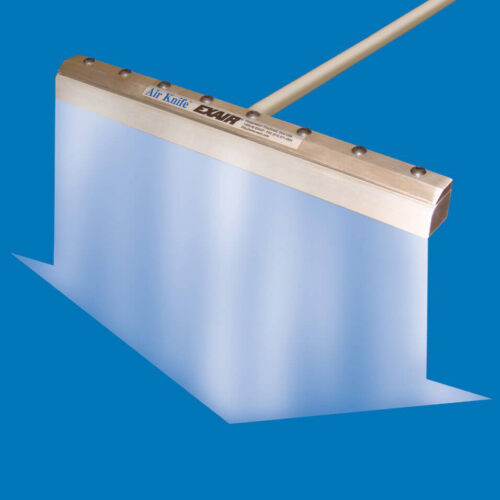

Standard Air Knife

- Good choice when a lower purchase price is desired

- Powerful and even airflow with good speed

- Higher operating cost than Super Air Knife

- Higher dBA value compared to Super Air Knife

- Air gain ratio of 30:1

- Compressed air inlets on each end of the air knife

- The air knife is 25 mm longer than the airflow length

Full-Flow Air Knife

- Good choice for tight spaces

- Good performance

- Minimum purchase price

- Higher operating cost than Super Air Knife

- Air gain ratio of 30:1

- Minimum size

- Compressed air inlet on the back as standard

- Airflow length and total air knife length are the same

Contact one of our experts

Call, email or why not book a web meeting with one of our experts in the product area EXAIR Compressed Air Products. We will advise you on the most suitable product or solution to achieve an efficient and safe result in your specific process.

A short web meeting is usually a time-efficiently way to gather the information we need to advise on the right solution. We can then quickly and easily obtain information on the various factors that may influence the choice of equipment and solution to achieve the most effective result. Sometimes a site visit may also be appropriate, depending on your preference. Of course, it is equally possible to call or email!

When suggesting a suitable product or solution, we look at function, longevity, quality, choice of materials, and operating and maintenance costs. Our goal is to deliver a sustainable solution that creates added value for you as a customer.

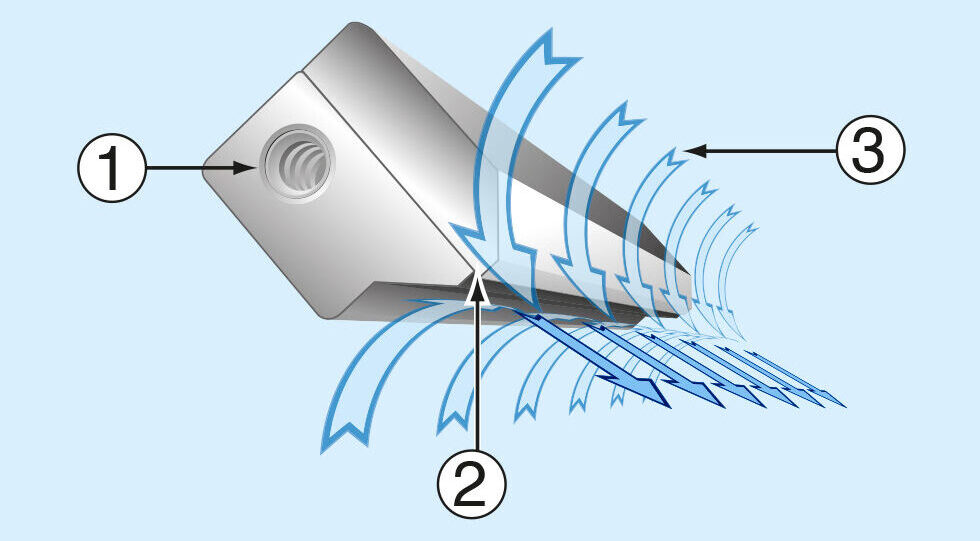

How the EXAIR Super Air Knife works

Compressed air flows through an inlet (1) into the plenum chamber of the Super Air Knife. The flow is directed to a precise, slotted orifice. As the primary airflow exits the thin slotted nozzle (2), it follows a flat surface that directs the airflow in a perfectly straight line. This creates a uniform sheet of air across the entire length of the Super Air Knife. Velocity loss is minimised and force is maximised as the room air (3) is entrained into the primary airstream at a ratio of 40:1. The result is a well defined sheet of laminar airflow with hard-hitting force and minimal wind shear.

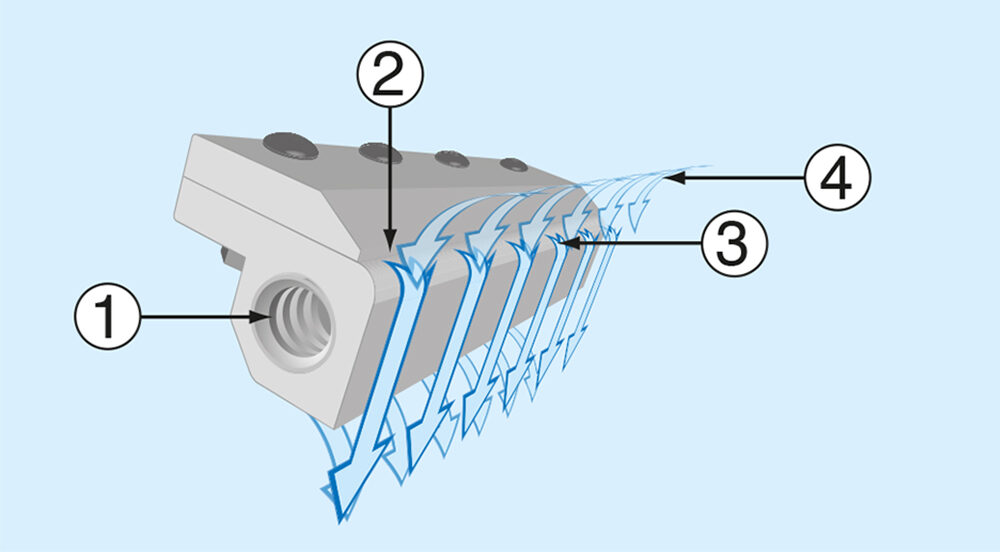

How the EXAIR Standard Air Knife works

Compressed air flows through the inlet (1) It is then throttled through a thin nozzle (2) extending the length of the Standard Air Knife. This primary airstream adheres to the Coanda profile (3), which turns it 90° and directs the flow down the face of the unit. The primary stream immediately begins to entrain surrounding air (4), for an amplification ratio of 30:1 at 6″ (152mm) away.

Documents for download

Book a web meeting

Book a quick and easy online meeting with one of our product experts to go through your questions and concerns about different products, issues or solutions.

Quick response time & technical support

We are available weekdays 08-16.30!

Knowledge base

We would like to share our knowledge and experience with you. In the Knowledge Bank you will find a variety of questions, explanations and process descriptions in our different product areas.