BlueFil® - structured demister

BlueFil® is an innovative, structured demister with high separation efficiency and low pressure drop.

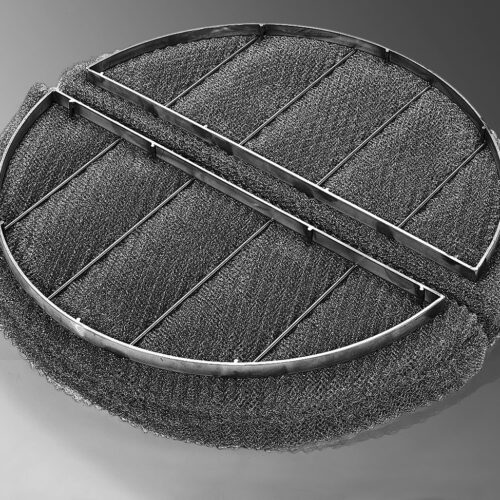

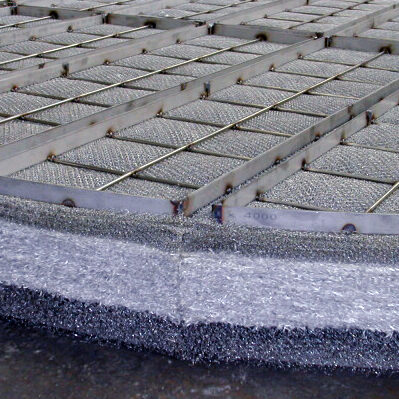

BlueFil® consists of a unique, open pyramid structure where virtually all threads are perpendicular to the gas stream, leading to a high degree of droplet separation.

The open structure of BlueFil® reduces the risk of clogging and is easy to rinse off without damaging the demister.

- Product information

- Checklist process data

- Documentation & videos

- General info Droplet separation

- Supplier information

- Send saved products to yourself, or as a quote request to Hansa

Innovative, unique structured droplet separator

BlueFil®'s construction

BlueFil® consists of a unique, open pyramid structure where virtually all threads are perpendicular to the gas stream, leading to a high degree of droplet separation.

The open structure of BlueFil® reduces the risk of clogging and is easy to rinse off without damaging the demister.

Areas of application

In addition to droplet separation, BlueFil® is successfully used in various applications where droplets and particles need to be coalesced and then filtered and separated.

BlueFil® is used, for example, in the production of sulphuric acid, the manufacture of artificial fertilisers and in a variety of other applications in the chemical industry.

Checklist important parameters

In order to offer an effective and sustainable solution, below are a number of process parameters that are important to consider when selecting and designing a droplet separator.

Sometimes it is difficult or even impossible to obtain information and data regarding the specific process. Together with our suppliers, we have extensive experience and we can make sound assumptions as a basis for designing the best solution for the process.

| Operating data | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gas | Unit | ||||||||||

| Maximum gas volume flow | m³/h | ||||||||||

| Gas density (operating conditions) | kg/m³ | ||||||||||

| Kinematic gas viscosity | mm²/s (cSt) | ||||||||||

| Operating pressure | bar (a) | ||||||||||

| Operating temperature | °C | ||||||||||

| Operating data | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Liquid | Unit | ||||||||||

| Liquid content | kg/h | ||||||||||

| Liquid density | kg/m³ | ||||||||||

| Surface tension | nM/m | ||||||||||

| Dynamic viscosity of the liquid | mPass | ||||||||||

| Geometrical data | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Data | Info/unit | ||||||||||

| Flow direction | horizontal or vertical | ||||||||||

| Installed in column | column or pipe | ||||||||||

| Column diameter or dimension | mm | ||||||||||

| Opening for installation | manhole or vessel flange | ||||||||||

| Requirements | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Data | Info/unit | ||||||||||

| Type of mist eliminator | wire mesh or vane type | ||||||||||

| Type of material | Please specify | ||||||||||

| Separation efficiency | % | ||||||||||

| Separation efficiency/Limit drop size | µm | ||||||||||

| Maximum pressure drop | mbar | ||||||||||

| Other requirements | Please specify | ||||||||||

Choose the right product for effective and optimised droplet separation

Every process is unique. The Knowledge base provides information on how droplet separation works and what questions need to be answered to achieve an effective and sustainable solution.

Begg Cousland Envirotec has vast know-how and experience in the field of droplet separation with a complete range of demisters, coalescers and candle filters.

Begg Cousland Envirotec has vast know-how and experience in the field of droplet separation with a complete range of demisters, coalescers and candle filters.

Many applications may be similar at a first glance, but there are often small differences that are crucial to consider for an optimal solution. With an extensive experience in many industries, Begg Cousland's technical team are able to deliver the most effective solution for a specific problem and process.

Our customer promise

Right solution, technical expertise and commitment is what you can expect from us as your partner or supplier.

Support & service

We offer the support you need to optimise your droplet separation and provide a sustainable solution.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.