Cabinet Cooler NEMA 12 (IP54) - for cooling electronic enclosures and control cabinets

Dust and oil-tight system, ideal for industrial environments without liquids.

- Suitable for general industrial environments without liquids or corrosive substances

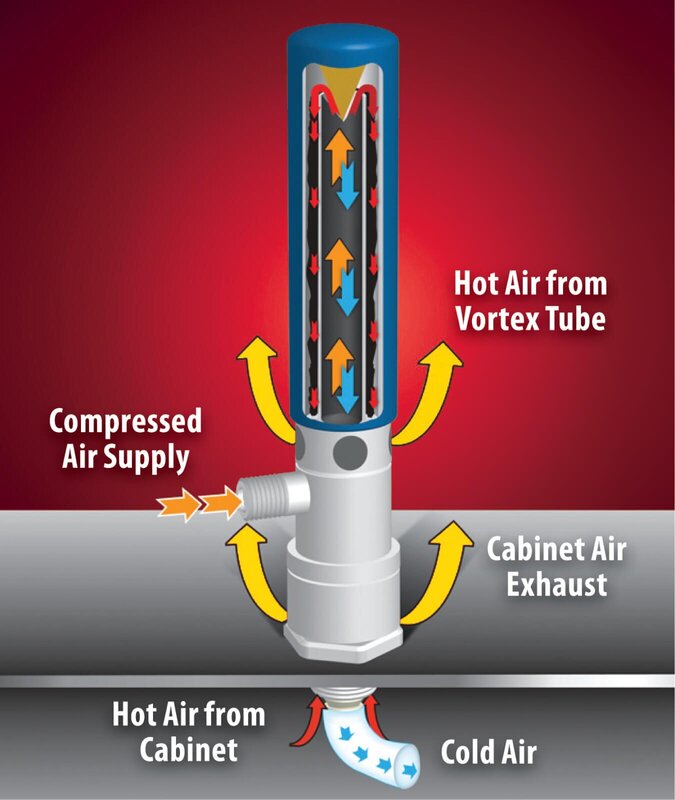

- Includes a vortex tube to produce cold air from compressed air, without moving parts.

- All cabinet coolers are UL certified and CE compliant.

- Product information

- Technical data

- Documentation & videos

- Supplier information

- Send saved products to yourself, or as a quote request to Hansa

EXAIR NEMA 12 (IP54) control cabinet cooling systems are dust and oil tight. They are ideal for general industrial environments without liquids or corrosives.

The EXAIR NEMA 12 (IP54) cabinet cooler is particularly suitable for systems that only need cooling from time to time. If temperatures rise in the summer and the enclosure is no longer sufficiently cooled, the control cabinet cooling system offers a solution. Even in environments where the ambient temperature is generally high or where the air contains a lot of dust or dirt, switch cabinet coolers are often the only solution. In these circumstances, the fans are of little use and only blow dust or dirt into the control cabinet.

Devices operate with difficulty at high temperatures and break down much faster. Dusty rooms don't just require cooling in the control cabinet to keep out dirt and dust.

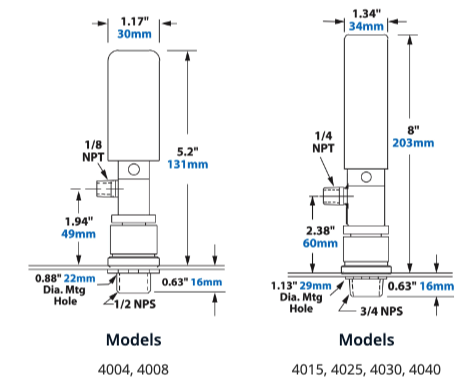

| Type | Material | Air consumption | Sound level | Capacity (Btu/h) | Capacity (Kcal/h) |

|---|---|---|---|---|---|

| 4004 | Aluminium | 113 | 59 dBA*. | 275 | 69 |

| 4008 | Aluminium | 227 | 67 dBA*. | 550 | 139 |

| 4015 | Aluminium | 425 | 73 dBA*. | 1000 | 252 |

| 4025 | Aluminium | 708 | 74 dBA*. | 1700 | 428 |

| 4030 | Aluminium | 850 | 74 dBA*. | 2000 | 504 |

| 4040 | Aluminium | 1133 | 78 dBA*. | 2800 | 706 |

*With optional silencer installed. Cooling capacity @6,9 bar inlet pressure. Air consumption in SLPM.

Documents for download

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

The product range includes air knives, blow nozzles, blow guns, pneumatic vacuum conveyors and products for discharging static electricity.

EXAIR products are used in the manufacturing industry for

- blowing clean using compressed air

- cooling

- drying

- surface treatment

- material transport (suction conveyors)

- industrial cleaning

- discharge of static electricity

EXAIR was founded in 1983 with the aim of providing the manufacturing industry with safer and more efficient air-powered products. The basic principle was to manufacture and supply the market with high quality products at a reasonable price.

Our full range of products

Extensive range of products focusing on function, quality and sustainability

Quick response time & technical support

We are available weekdays 08-16.30!

Book a web meeting

Book a quick and easy online meeting with one of our product experts to go through your questions and concerns about different products, issues or solutions.