EXAIR Mini Super Air Nozzles™

The EXAIR Mini Super Air 283 SLPM, 17 Nm3/h @5,5bar.

- Product information

- Technical data

- Documentation & videos

- Supplier information

- Send saved products to yourself, or as a quote request to Hansa

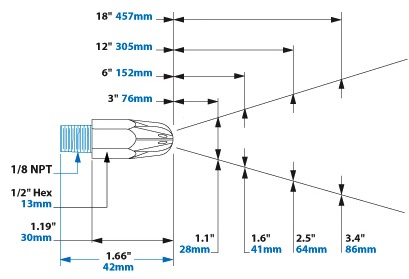

EXAIR Mini Super Air nozzles provide powerful and concentrated air patterns. Compared to the larger Super Air nozzles, they generate less noise, consume less air and have less blowing force. The air pattern of these nozzles is 255 grams at 5.5 bar at 305 mm distance, dimension 41 mm at 152 mm distance with an air consumption of 17 Nm3/hour. Noise emissions are only 71 dBA.

EXAIR Mini Super Air nozzles, model number 1102, are available in 316 stainless steel or PEEK (plastic) with an internal thread of 1/8" BSP or 1/8" NPT; model 1103 is available in aluminium and 316 stainless steel and with an external thread of 1/8" BSP or 1/8" NPT.

| Type | Material | Thread | Air consumption | Strength | Sound level |

|---|---|---|---|---|---|

| 1102, 1103 | Zinc Aluminium alloy | 1/8" F, 1/8" M | 17 Nm3/h | 255 grams | 71 dBA |

| 1102-PEEK, 1103-PEEK | PEEK | 1/8" F, 1/8" M | 17 Nm3/h | 255 grams | 71 dBA |

| 1102SS, 1103SS | RVS316 | 1/8" F, 1/8" M | 17 Nm3/h | 255 grams | 71 dBA |

Force measured at 305 mm at 5.5 bar, sound level at 1 metre distance.

Documents for download

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

The product range includes air knives, blow nozzles, blow guns, pneumatic vacuum conveyors and products for discharging static electricity.

EXAIR products are used in the manufacturing industry for

- blowing clean using compressed air

- cooling

- drying

- surface treatment

- material transport (suction conveyors)

- industrial cleaning

- discharge of static electricity

EXAIR was founded in 1983 with the aim of providing the manufacturing industry with safer and more efficient air-powered products. The basic principle was to manufacture and supply the market with high quality products at a reasonable price.

Our full range of products

Extensive range of products focusing on function, quality and sustainability

Quick response time & technical support

We are available weekdays 08-16.30!

Book a web meeting

Book a quick and easy online meeting with one of our product experts to go through your questions and concerns about different products, issues or solutions.