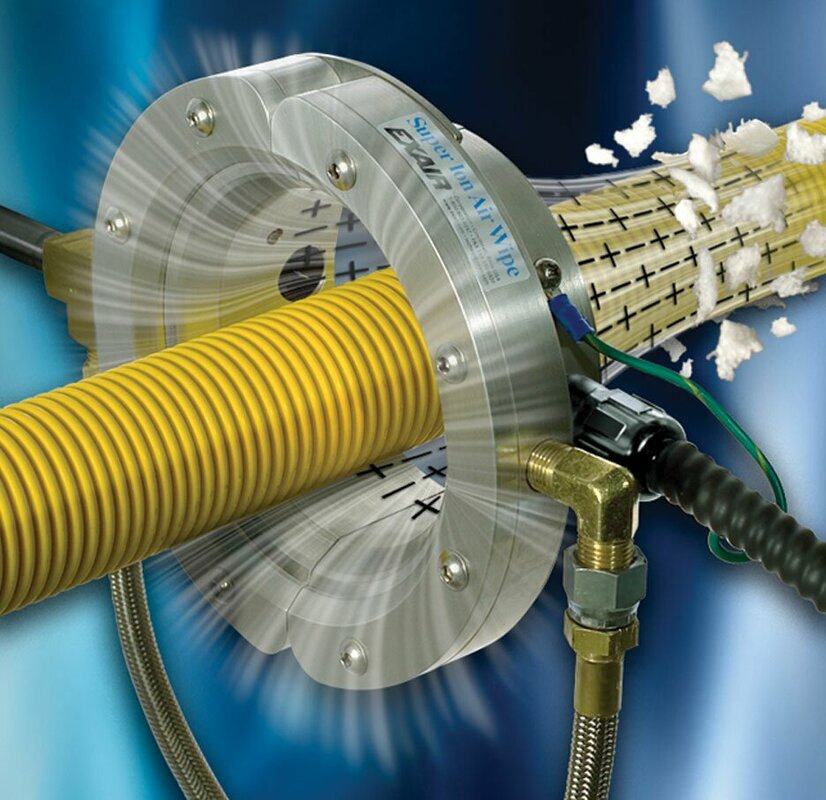

Gen4 Super Ion Air Wipe™ - efficient static removal with 360° airflow

Uniform 360° ionised airflow to eliminate static electricity.

EXAIR Super Ion Air Wipes remove static electricity from plastics, tapes, paper sheets and other product surfaces where cracks, jams or dangerous static discharges cause problems.

- Product information

- Documentation & videos

- Supplier information

- Send saved products to yourself, or as a quote request to Hansa

The laminar, ionised airflow blows the surface clean of static particles, dust and other contaminants. Production speed, product and surface quality are significantly increased.

The Super Ion Air Wipe provides a uniform 360° ionised airflow that can be easily clamped around a component to eliminate static electricity and contamination.

It is ideal for use on pipes, cables, extruded shapes, hoses, wires and much more. The high-volume, high-velocity stream adheres to the surface and wipes it away with ions that eliminate static electricity.

The airflow remains attached to the surface and operates effectively at great distances from the Gen4 Super Ion Air Wipe installation site. An optional pressure regulator provides infinite control over air volume and speed.

Features and functions

- Available in 2"" (51 mm) or 4"" (102 mm) versions.

- Available as a complete set with Super Ion Air Wipe, Gen4 power source, air filter and reduction valve shim kits.

Documents for download

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

The product range includes air knives, blow nozzles, blow guns, pneumatic vacuum conveyors and products for discharging static electricity.

EXAIR products are used in the manufacturing industry for

- blowing clean using compressed air

- cooling

- drying

- surface treatment

- material transport (suction conveyors)

- industrial cleaning

- discharge of static electricity

EXAIR was founded in 1983 with the aim of providing the manufacturing industry with safer and more efficient air-powered products. The basic principle was to manufacture and supply the market with high quality products at a reasonable price.

Our full range of products

Extensive range of products focusing on function, quality and sustainability

Quick response time & technical support

We are available weekdays 08-16.30!

Book a web meeting

Book a quick and easy online meeting with one of our product experts to go through your questions and concerns about different products, issues or solutions.