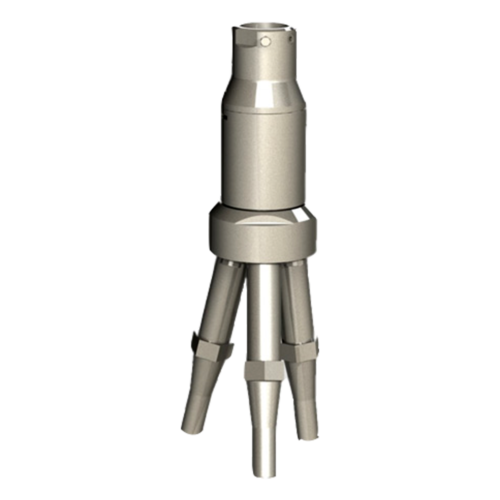

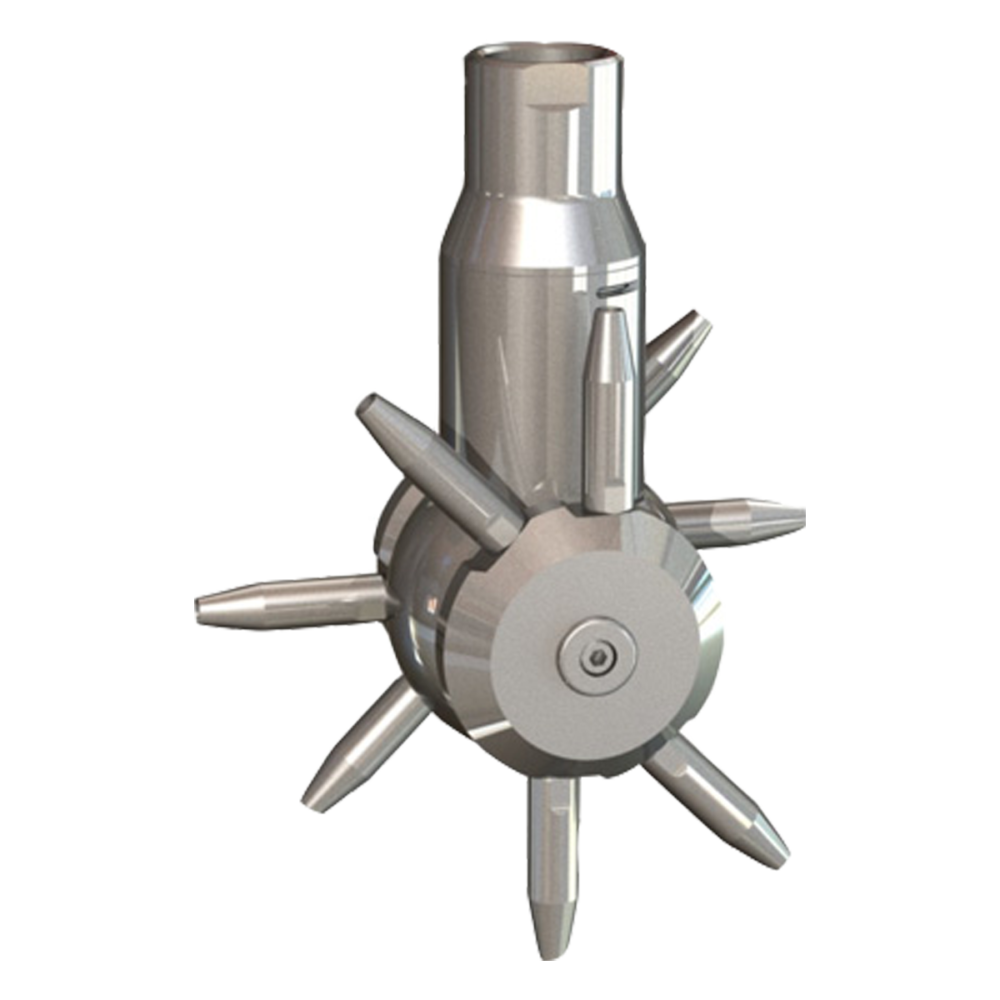

Orbitor Dual Head - Tank cleaning machine

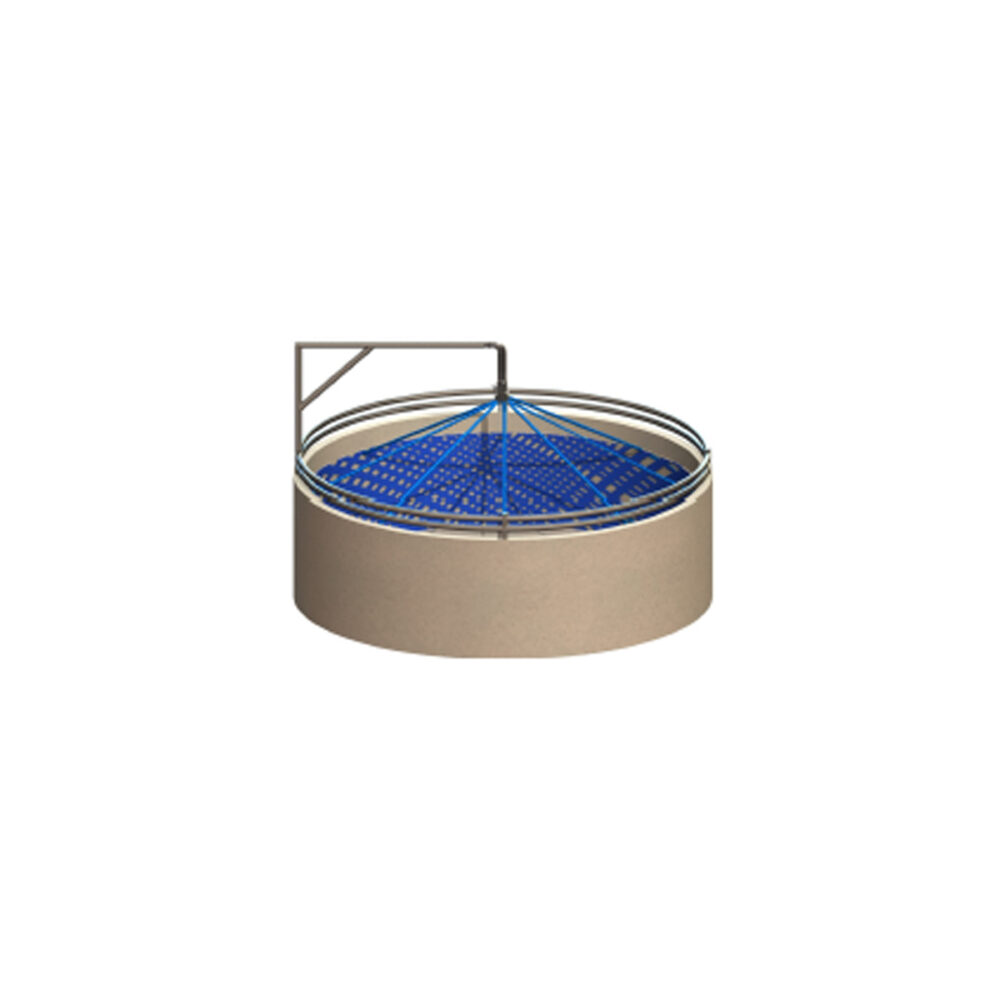

Orbitor Dual Head is a tank cleaning machine with a high impact, effective spray, ideal for open tanks and vessels up to Ø 30 m. The wash pattern can be set from 180° to 85° down wash.

In order to reduce water consumption, each Orbitor Dual Head is customised, taking into account the time required per cleaning cycle, available pressure, and flow requirements.

- Product information

- Technical data

- Documentation & videos

- General info Tank cleaning

- Supplier information

- Certifications

- Send saved products to yourself, or as a quote request to Hansa

Design features

- Ideal for open tanks and vessels

- The wash pattern can be set from 180° to 85° down wash

- Suitable for tanks and vessels up to Ø 30 m (based on 180° down wash)

- High impact spray

- Efficient wash cycle

- Low maintenance and extended operating life

- Self-lubricating

- ATEX on request

- To reduce water consumption, each tank cleaning machine is manufactured according to the customer's needs, taking into account the time required per wash cycle, available pressure, and flow requirements.

| Spray angle | 180° - 85° down wash |

|---|---|

| Flow rate | 6.6 -16.5 m3/h |

| Standard material - Body & Cap Nut | 316L |

| Connection | 1 1/2" BSP |

| Dimensions | See Datasheet |

| Max temperature | See Datasheet |

Flow rates, spray angles & connections

For more information regarding flow rate, throw length and cleaning cycle duration, see Datasheet under the tab 'Documentation & videos'.

| Flow rate (m3/h) @ Differential pressure (kg/cm2), Density (1 SG) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle size | Connection | Spray angle | 5 kg/cm2 | 6 kg/cm2 | 7 kg/cm2 | 8 kg/cm2 | 9 kg/cm2 | 10 kg/cm2 | ||||||

| 4 mm | 1 1/2" | 180° down wash* | 6,6 | 7,3 | 7,5 | 7,8 | 8,1 | 8,4 | ||||||

| 5 mm | 1 1/2" | 180° down wash* | 7,8 | 8,8 | 9,3 | 9,8 | 10,3 | 10,8 | ||||||

| 6 mm | 1 1/2" | 180° down wash* | 9,2 | 10,0 | 10,9 | 11,8 | 12,5 | 13,0 | ||||||

| 7 mm | 1 1/2" | 180° down wash* | 10,8 | 11,8 | 12,7 | 13,5 | 14,3 | 15,0 | ||||||

| 8 mm | 1 1/2" | 180° down wash* | 11,2 | 12,2 | 13,1 | 13,9 | 14,7 | 15,6 | ||||||

| 9 mm | 1 1/2" | 180° down wash* | 11,6 | 12,7 | 13,5 | 14,5 | 15,5 | 16,5' | ||||||

* Note that the flow rate in this table is for 180° down wash, but it is also possible to get a spray of 180°-85° down wash or 360°. See data sheet for more info.

Download PDF

Choose the right product for optimised tank cleaning

Choosing the right product is mainly determined by the type of media the tank contains and the diameter of the tank. In addition, there are a number of other factors to consider in order to achieve an effective tank cleaning process.

The Knowledge base provides more information about the difference between various types of tank cleaning nozzles, tank or vessel design, purpose of the tank cleaning process, importance of the washing liquid, etc.

Dasic Group was established in the 1960s and specialises in the manufacture of tank cleaning machines for industrial and marine applications. Dasic's product technology has been used in a wide range of applications all over the world and meets the high demands of food and brewing industries.

Tank cleaning is an important part of companies' process efficiency and Dasic's main focus is to deliver superior cleaning with short wash cycles, as well as optimised water, energy and chemical consumption. The Dasic Group is also very flexible when it comes to providing customised solutions when needed.

Dasic's customer promise is:

- Quality Design - Optimised Design, Low Life Cycle Costs

- Quality Products - Proven Technology, High Efficiency, Low Maintenance

- Quality Control - Rigorous Inspection, Full Performance Testing Prior to Shipping

- Quality Service - Rapid Response Time, Immediately Available Product, Global Representation

Some of Dasic's certifications include ISOQAR (ISO 9001), ATEX, UKAS and Bureau Veritas.

Dasic Group Certifications & Approvals

For a full list of our suppliers' various types of certifications, click here.

Our customer promise

Right solution, technical expertise and commitment is what you can expect from us as your partner or supplier.

Support & service

We offer the support you need to optimise your process, minimise risk and achieve a sustainable solution.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.