EXAIR Line Vac air operated conveyors

EXAIR Line Vac is an innovative solution for efficient and maintenance-free material transport. Using compressed air, Line Vac creates a powerful vacuum that quickly and easily transports a wide variety of materials - plastic pellets, pellets, shavings, scrap, food products, small components, etc.

EXAIR Line Vac helps to improve productivity and efficiency in production and is available in several different models in both aluminium and stainless steel, including special versions for high temperature and sanitary environments.

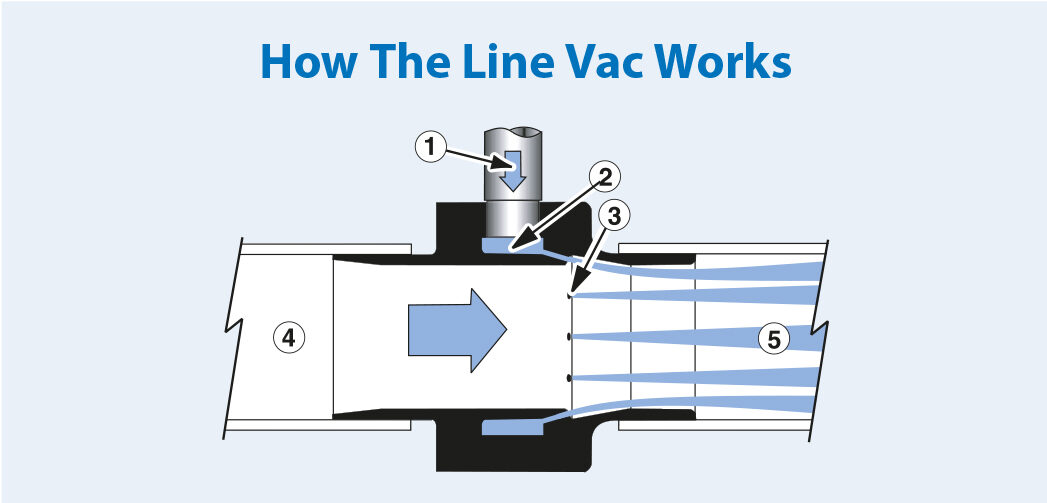

How does the EXAIR Line Vac pneumatic conveyor work?

EXAIR Line Vac is a pneumatic conveyor powered by compressed air. The Line Vac is connected to a hose or pipe, thus creating a powerful in-line conveyor.

By injecting a small amount of compressed air through a few nozzles, a vacuum is created at one end and a high outflow at the other, allowing for fast and efficient transport of materials.

Line Vac has no moving parts and requires minimal maintenance.

Compressed air flows through the inlet (1) into an annular plenum chamber (2). It is then injected into the throat through directed nozzles (3). These jets of air create a vacuum at the intake (4) which draws material in and accelerates it through the unit (5) for conveying over long vertical or horizontal distances.

Compressed air flows through the inlet (1) into an annular plenum chamber (2). It is then injected into the throat through directed nozzles (3). These jets of air create a vacuum at the intake (4) which draws material in and accelerates it through the unit (5) for conveying over long vertical or horizontal distances.

Contact one of our experts

Call, email or why not book a web meeting with one of our experts in the product area EXAIR Compressed Air Products. We will advise you on the most suitable product or solution to achieve an efficient and safe result in your specific process.

A short web meeting is usually a time-efficiently way to gather the information we need to advise on the right solution. We can then quickly and easily obtain information on the various factors that may influence the choice of equipment and solution to achieve the most effective result. Sometimes a site visit may also be appropriate, depending on your preference. Of course, it is equally possible to call or email!

When suggesting a suitable product or solution, we look at function, longevity, quality, choice of materials, and operating and maintenance costs. Our goal is to deliver a sustainable solution that creates added value for you as a customer.

Which type of EXAIR Line Vac pneumatic conveyor should I choose?

There are four different types of Line Vac pneumatic conveyors, with slightly different applications. Contact us to discuss what is most suitable for your process and operations.

Standard Line Vac

Made of aluminium and stainless steel, it is suitable for most types of transport. Aluminium is the cheaper option. The standard stainless steel models (type 303) are ideal for processes with corrosive material/environment or in processes that lead to high wear.

Threaded Line Vac

Uses standard pipe fittings, making it easy to build a complete system with standard components.

Heavy Duty Line Vac

LäSuitable for robust, industrial applications. Made of hardened alloy material to withstand wear and tear and long-distance transport.

Sanitary Flange Line Vac

Made of 316 stainless steel and compatible with ISO 2852 sanitary flanges, which are particularly useful in applications where hygiene and cleaning are essential.

Documents for download

Book a web meeting

Book a quick and easy online meeting with one of our product experts to go through your questions and concerns about different products, issues or solutions.

Quick response time & technical support

We are available weekdays 08-16.30!

Knowledge base

We would like to share our knowledge and experience with you. In the Knowledge Bank you will find a variety of questions, explanations and process descriptions in our different product areas.