Our complete range of spray nozzles and systems

Listed below is our complete range of spray nozzles and systems for various spray applications, in alphabetical order.

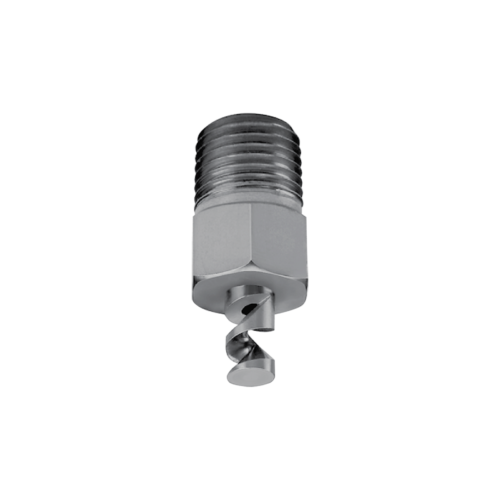

EZWT

- 0.134 - 23.9 l/min

- 70° - 110°

- Snap release spray nozzle system

- Tangential hollow cone nozzle

FF

- 0.0518 - 1400 l/min

- 105° - 145°

- Extra wide spray angle

- Flat fan nozzle with deflector spray

Finz ®

- 7 - 65 Nm3/h @ 0.7 - 6 bar

- Air nozzle

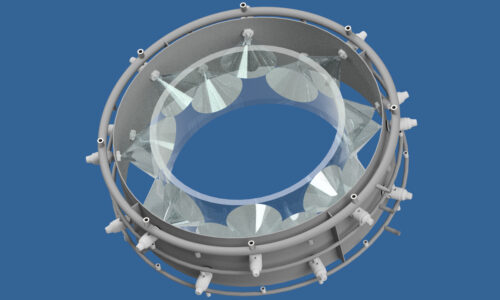

FlexFlow™ Spray Control System | Hansa Engineering

- Spray control system for intermittent spraying

- Plug-and-play

- High precision

- Flexible automation

HA

- 0.9 - 320.16 l/hour

- 15° - 120°

- Filter optional

- Fine mist or fog

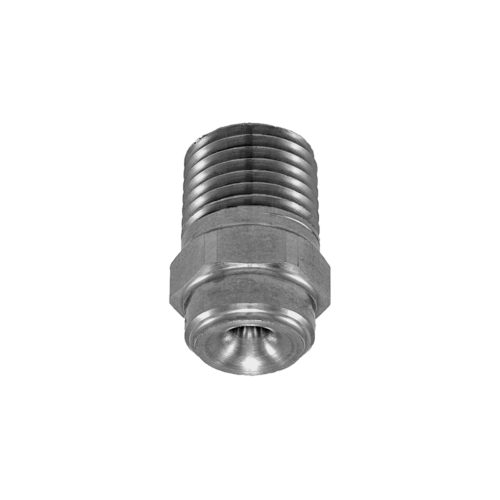

L

- 0.526 - 32.5 l/min

- 90°

- Fine mist or fog

- Small spiral nozzle

MaxiPass

- 2.64 - 5700 l/min

- 30° - 120°

- Extra large free passage

- Axial full-console nozzle

MaxiPass®L

- 0.325 - 11.4 l/min

- 51° - 134°

- Low flow rates

- Extra large free passage

- Axial full-console nozzle

MicroWhirl

- 0.0323 - 1.44 l/min

- 70°

- Compact design

- Standard filter 70 microns

- Fine mist or fog

N

- 11.4 - 2260 l/min

- 90°, 120°

- Large free passage

- Certified for firefighting

- Spiral full cone nozzle

NC

- 7.63 - 35200 l/min

- 60° - 120°

- High flow rates

- Axial full-console nozzle

NCFL

- 350 - 19700 l/min

- 60° - 120°

- High flow rates

- Large free passage

- Axial full-console nozzle

NCJ

- 19.3 - 9820 l/min

- 15° - 30°

- High impact, high velocity spray

- Axial hollow cone nozzle

NCK

- 19.3 - 9820 l/min

- 15° - 30°

- High impact spray

- Axial full-console nozzle

NCS

- 7.63 - 2200 l/min

- 70° - 110°

- Small projection

- Axial full-console nozzle

Choose the right spray nozzle for an optimised spray process

Each type of spray nozzle has a specific flow rate, spray pattern and droplet size. To optimise the spray process, it is important to understand how different parameters affect the choice of spray nozzle and solution.

-

What is the function of the spray nozzle and the spray process?Read the full answer

The first step when choosing the right spray nozzle is to define the function and application of the spray process, such as cooling a gas, washing a tank or flushing a conveyor belt. Type of spray nozzle, thus also spray pattern and droplet size, are important to consider in order to optimise the spray process.

-

Which droplet size is most suitable for the spray process?Read the full answer

Droplet size is often critical in optimising a spray process. Many processes, such as gas cooling and gas scrubbing, depend on exposing the maximum total liquid surface area. The liquid then needs to be distributed in a large number of small droplets to create as much total surface area as possible. Other spray processes ...

-

What surface should the spray cover? How should the nozzle be positioned?Read the full answer

The position of the nozzle over the target (D) and the area to be covered by the spray (B) are important to know in order to choose the right spray angle (A). The spray angle is measured near the nozzle orifice and the droplets are immediately affected by external forces such as gravity, air and gas flow.

-

Desired flow rate? Available pressure?Read the full answer

Desired volume flow depends on the specific spray process. Most spray processes have general rules of thumb for flow ranges, but in many cases on-site testing is needed to achieve the right results.

-

What type of liquid is used in the spray process?Read the full answer

A liquid's specific gravity, viscosity and the presence of particles affect the spray characteristics of the nozzle.

-

Are there external factors affecting the nozzle spray?Read the full answer

Sometimes the spray is affected by external forces such as process gas flows, air flows or wind.

-

Which material is most suitable for the spray process?Read the full answer

Listed below are a number of factors that should be considered when selecting materials for a specific nozzle. An incorrect choice of material is likely to affect the performance and life of the nozzle. We are happy to help and advise on which material is most suitable in your ...

-

What are the benefits of an optimised spray process?Read the full answer

There are many factors to consider when selecting a nozzle for a specific spray process. An optimised spray process can make a big difference, contributing to: improved product and process quality increased production and reduced time for unplanned stops reduced maintenance costs lower operating costs by reducing the use of ...

Documents for download

Previous projects

Read more about a selection of customised solutions and projects we have carried out for our industry colleagues and partners.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.

FAQ Spray nozzles & systems

Here you will find a variety of questions and answers about spray nozzles and spray systems.