Raflux Ring - Random packings

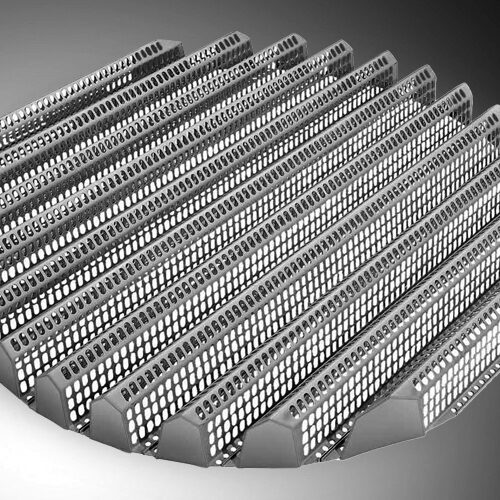

Raflux rings are a second generation tower packing which are generally classified as a standard tower packing. The Raflux ring has evolved from the cylindrical ring.

The Raflux Ring has an open structure compared to the cylindrical ring, which ensures a regular flow through the packing, reducing the pressure drop whilst maintaining the same surface area of the packing.

- Product information

- Technical data

- Documentation & videos

- Checklist process data

- General info Column internals

- Supplier information

- Send saved products to yourself, or as a quote request to Hansa

Design features

- Standard random packing with an open structure

- Lower pressure drop compared to a cylindrical ring

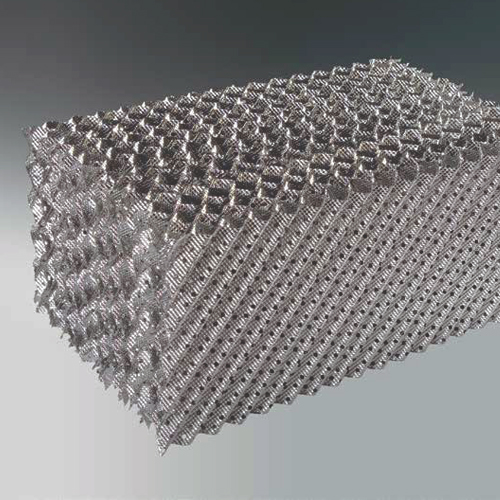

- Available in a variety of materials and sizes

- Also known as Pall Ring

- One of the most commonly used random packings in industry

Listed below are different sizes of Raflux Ring random packings. Under the tab 'Documentation & videos' you will find data sheets with additional information.

Raflux Ring Plastics

| Data refer to polypropylene | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type size | Weight kg/m3 | Surface area m2/m3 | Void fraction in % | ||||||||||

| 25-0 | 90 | 220 | 90 | ||||||||||

| 25-8 | 79 | 220 | 91 | ||||||||||

| 35-0 | 78 | 160 | 92 | ||||||||||

| 38-8 | 72 | 175 | 92 | ||||||||||

| 50-1 | 52 | 110 | 94 | ||||||||||

| 50-8 | 58 | 110 | 94 | ||||||||||

| 90-8 | 38 | 86 | 96 | ||||||||||

Available materials: PP, PPH, PE, PVC, C-PVC, PVDF, PFA, ECTFE and others on request

Raflux Ring Metals

| Data refer to stainless steel 1.4301 (AISI 304) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type size | Weight kg/m3 | Surface area m2/m3 | Void fraction in % | ||||||||||

| 15-3 | 340 | 360 | 95 | ||||||||||

| 25-5 | 363 | 215 | 95 | ||||||||||

| 38-5 | 256 | 135 | 97 | ||||||||||

| 50-5 | 207 | 112 | 97 | ||||||||||

| 70-7 | 198 | 78 | 98 | ||||||||||

| 90-8 | 179 | 65 | 98 | ||||||||||

Available materials: Carbon steel, stainless steel, Hastelloy, titanium, and others on request

Raflux Ring Ceramics

| Data refer to stoneware | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type size | Weight kg/m3 | Surface area m2/m3 | Void fraction in % | ||||||||||

| 25-3 | 620 | 220 | 73 | ||||||||||

| 35-4 | 540 | 165 | 76 | ||||||||||

| 50-5 | 550 | 120 | 78 | ||||||||||

| 75-8 | 540 | 98 | 78 | ||||||||||

| 80-9 | 520 | 80 | 79 | ||||||||||

| 90-9 | 504 | 77 | 78 | ||||||||||

Available material: Stoneware and others on request

Checklist important parameters

Listed below are a number of parameters that are important to consider when selecting the right type and size of random packing in order to achieve an effective and sustainable solution.

Sometimes it is difficult or even impossible to obtain information and data regarding the specific process. Together with our suppliers, we have extensive experience and we can make sound assumptions as a basis for designing the best solution for the process.

| Operating data | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gas | Unit | ||||||||||

| Type of gas | Please state | ||||||||||

| Gas volume flow (operating conditions) | m3/h | ||||||||||

| Gas density (operating conditions) | kg/m3 | ||||||||||

| Gas viscosity | mm2/s (cP) | ||||||||||

| Operating pressure | bar (a) | ||||||||||

| Operating temperature | °C | ||||||||||

| Operating data | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Liquid | Unit | ||||||||||

| Type of liquid | Please state | ||||||||||

| Liquid volume flow | m3/h | ||||||||||

| Liquid density | kg/m3 | ||||||||||

| Liquid viscosity | cP | ||||||||||

| Surface tension | mN/m | ||||||||||

| Geometrical data | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Data | Info/unit | ||||||||||

| Packing type and size | Please state (if known) | ||||||||||

| Specific surface area | m2/m3 (if known) | ||||||||||

| Packing height | mm | ||||||||||

| Column diameter | mm | ||||||||||

| Additional information/requirements | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Data | Info/unit | ||||||||||

| Material | Please specify | ||||||||||

| Fouling | Yes/No | ||||||||||

| Foaming | Yes/No | ||||||||||

| Other requirements/additional information | Please specify | ||||||||||

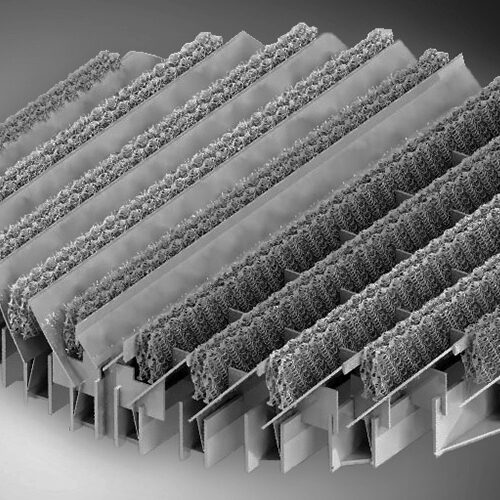

Optimised performance in mass and heat transfer processes

For optimised performance in a mass or heat transfer process it is important to understand the underlying principles and parameters that are important to consider when designing a column for flue gas cleaning, flue gas condensation or stripping.

Founded in 1976, RVT Process Equipment is a leading supplier and manufacturer of droplet separators, packings, column internals and other products for mass and heat transfer processes.

Founded in 1976, RVT Process Equipment is a leading supplier and manufacturer of droplet separators, packings, column internals and other products for mass and heat transfer processes.

RVT Process Equipment offers advanced engineering and technical support and has extensive experience in various processes and applications in the chemical and petrochemical industry, refineries, power plants, and pulp and paper. The R&D department houses fully equipped test units, available to carry out customer-specific tests when needed.

RVT Process Equipment has subsidiaries and manufacturing facilities in Knoxville, USA and in Kunchan, China.

Our customer promise

Right solution, technical expertise and commitment is what you can expect from us as your partner or supplier.

Support & service

We offer the support you need to optimise your process and develop a sustainable solution.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.