Super Air Amplifier™ - for powerful and efficient cooling, blowoff and ventilation

For the circulation of large volumes of air. Patented design with special shim disc.

- More air movement with less compressed air

- Compact, lightweight, portable

- Inlet and outlet can be easily connected to a pipe or hose

- Product information

- Technical data

- Documentation & videos

- Supplier information

- Send saved products to yourself, or as a quote request to Hansa

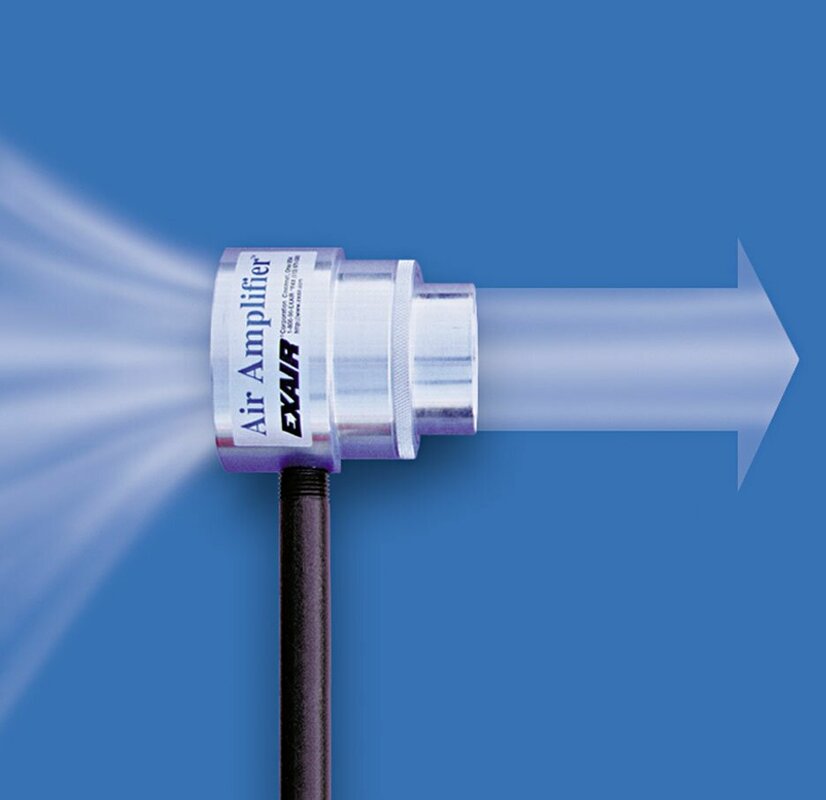

EXAIR air amplifiers provide the greatest gain and are the most efficient. The patented* design uses a special shim to hold the critical position of certain parts. The result is that a precise amount of compressed air is released in exactly the right places in relation to the core of the EXAIR air amplifier. These air jets produce a constant flow of outlet side diameter at high velocity across the outlet side diameter.

Ambient air is sucked through the air amplifier, resulting in even greater air amplification. The balanced airflow at the exhaust prevents "noise"; therefore, the EXAIR air amplifier is about 3 times quieter than standard air amplifiers.

EXAIR air amplifiers are supplied with a 0.003″" (0.08 mm) shim, which is ideal for most applications. The flow and power can be increased by replacing the shim with a thicker, i.e. 0.006″" (0.15 mm) or 0.009″ (0.23 mm) shim.

Advantages compared to fans:

- Compact, lightweight, portable

- No electricity required

- Power and flow adjustable

- Inlet and outlet can be easily connected to pipe or hose

- No moving parts - no maintenance

- Immediately on/off

Advantages compared to venturi nozzles and ejectors:

- More air displacement with less compressed air

- Greater air gain

- Low noise

- Complies with US OSHA pressure/noise regulations

- No internal constrictions

| Type | Air consumption | Reinforcement (quota) | Exhaust air volume | Air volume of 152 mm | Sound level |

|---|---|---|---|---|---|

| 120020 | 173 SLPM | 12 | 2066 SLPM | 6198 SLPM | 69 dBA |

| 120021 | 229 SLPM | 18 | 4132 SLPM | 12339 SLPM | 72 dBA |

| 120022 | 439 SLPM | 22 | 9650 SLPM | 28951 SLPM | 72 dBA |

| 120024 | 826 SLPM | 25 | 20659 SLPM | 61977 SLPM | 73 dBA |

| 120028 | 3396 SLPM | 25 | 84900 SLPM | 254700 SLPM | 88 dBA |

@5.5 bar. Model 120028 tested with 0.23 shim. All other models with 0.08 mm shim.

Documents for download

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

EXAIR Compressed air products are designed to optimise and streamline various industrial processes, and to improve the working environment.

The product range includes air knives, blow nozzles, blow guns, pneumatic vacuum conveyors and products for discharging static electricity.

EXAIR products are used in the manufacturing industry for

- blowing clean using compressed air

- cooling

- drying

- surface treatment

- material transport (suction conveyors)

- industrial cleaning

- discharge of static electricity

EXAIR was founded in 1983 with the aim of providing the manufacturing industry with safer and more efficient air-powered products. The basic principle was to manufacture and supply the market with high quality products at a reasonable price.

Our full range of products

Extensive range of products focusing on function, quality and sustainability

Quick response time & technical support

We are available weekdays 08-16.30!

Book a web meeting

Book a quick and easy online meeting with one of our product experts to go through your questions and concerns about different products, issues or solutions.