TF - Täyskartiosuutin

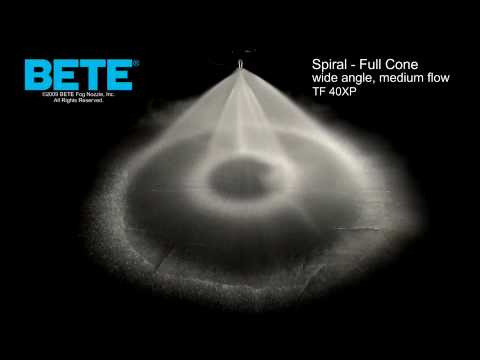

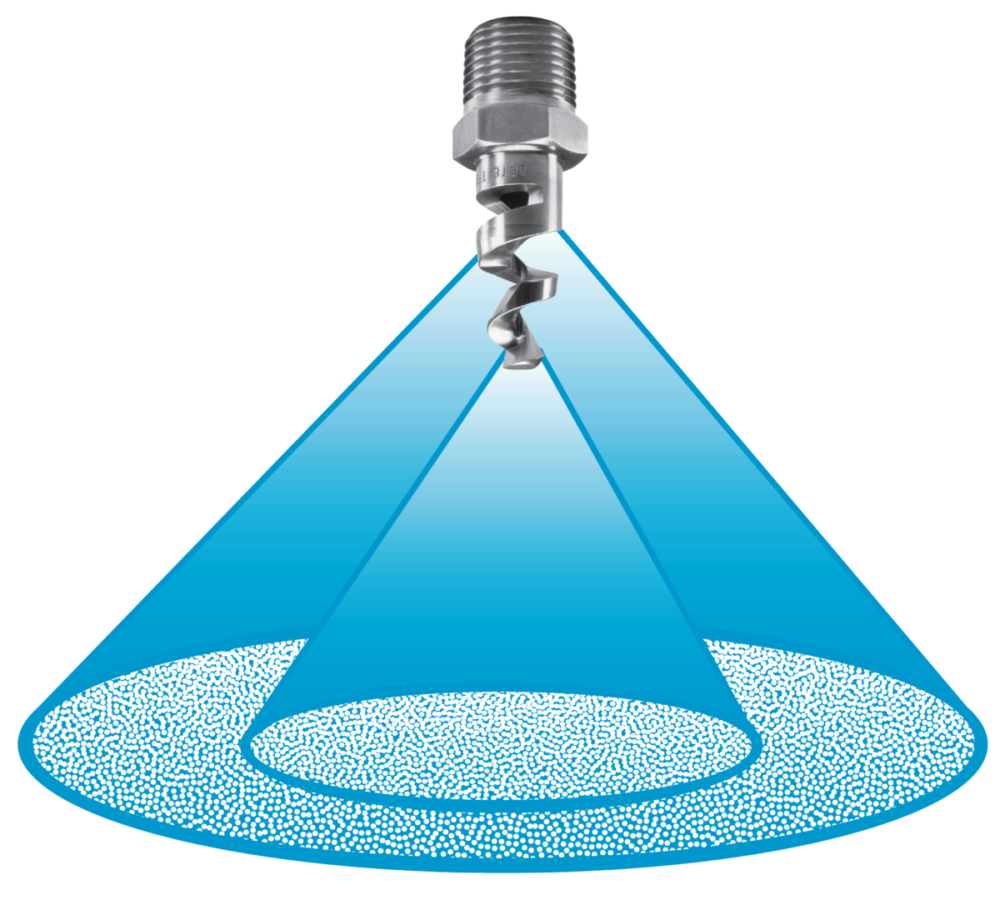

TF full cone nozzle generates fine atomisation with a high discharge velocity. There is a wide selection of spray angles and flow rates to choose from.

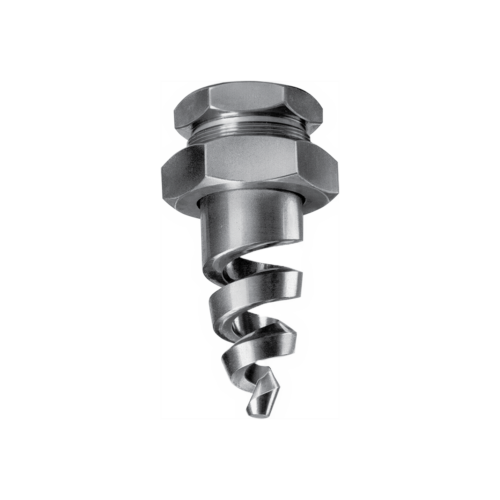

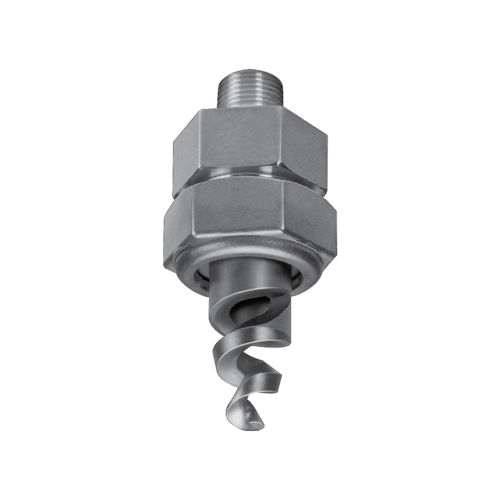

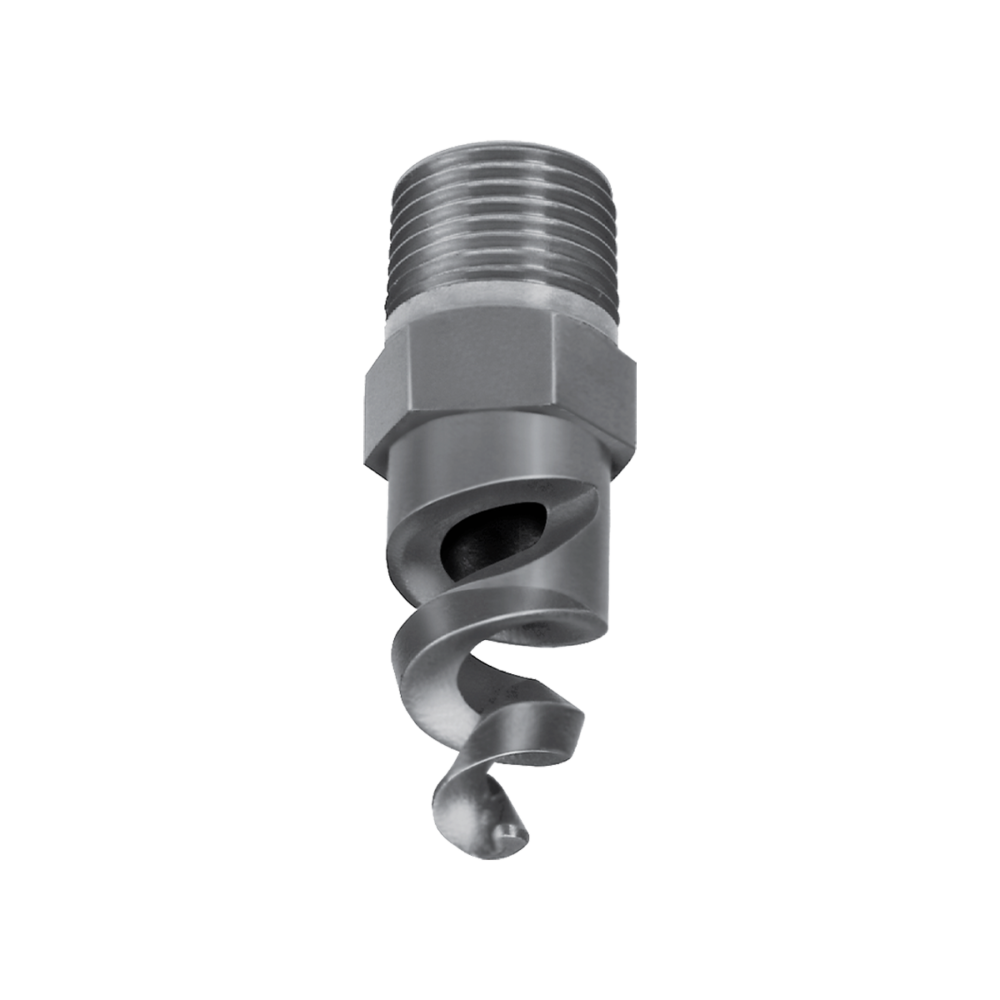

The TF nozzle has a large free passage, which reduces the risk of clogging. The TF is a spiral nozzle and is often used for quenching, gas scrubbing and evaporative cooling.

- Product information

- Technical data

- Documentation & videos

- General info Spray nozzles & systems

- Supplier information

- Certifications

- Send saved products to yourself, or as a quote request to Hansa

Design features

- High energy efficiency

- Large free passage

- Fine atomisation

- High discharge velocity

- Wide selection of spray angles and flow rates

- Commonly used for quenching, gas scrubbing, and evaporative cooling

| Spray pattern | Spiral nozzle - Full cone |

|---|---|

| Spray angle | 50° - 180° |

| Flow rate | 1.87 - 14000 l/min |

| Standard material - Body & Cap Nut | Brass, 316, PVC, Polypropylene, PTFE |

| Connection | 1/8" - 4" BSP/NPT |

| Dimensions | See Datasheet |

Flow rates, spray angles & connections

If a specific pressure is not listed below or in the nozzle datasheet, it is possible to calculate the nozzle flow rate at a given pressure by using the equation at the bottom of the datasheet.

| Flow rate (l/min) @ Differential pressure (bar), Density (1 SG) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle number | Connection | Spray angle | 0.3 bar | 1 bar | 3 bar | 4 bar | 7 bar | 30 bar | ||||||

| TF6 | 1/8", 1/4", 3/8" | 60°, 90°, 120°, 150°, 170° | - | 3,19 | 5,53 | 6,38 | 8,44 | 17,5 | ||||||

| TF8 | 1/8", 1/4", 3/8" | 60°, 90°, 120°, 150°, 170° | - | 5,93 | 10,3 | 11,9 | 15,7 | 32,5 | ||||||

| TF10 | 1/4", 3/8" | 60°, 90°, 120°, 150°, 170° | - | 9,11 | 15,8 | 18,2 | 24,1 | 49,9 | ||||||

| TF12 | 3/8" | 60°, 90°, 120°, 150°, 170° | - | 13,7 | 23,7 | 27,4 | 36,2 | 75,0 | ||||||

| TF14 | 3/8" | 60°, 90°, 120°, 150°, 170° | - | 18,5 | 32,0 | 37,0 | 48,9 | 101 | ||||||

| TF16 | 3/8" | 60°, 90°, 120°, 150°, 170° | - | 24,2 | 41,9 | 48,4 | 64,0 | 133 | ||||||

| TF20 | 3/8" | 60°, 90°, 120°, 150°, 170° | - | 37,6 | 65,1 | 75,2 | 99,5 | 206 | ||||||

| TF24 | 1/2" | 60°, 90°, 120°, 150°, 170° | - | 54,9 | 95,1 | 110 | 145 | 301 | ||||||

| TF28 | 1/2" | 60°, 90°, 120°, 150°, 170° | - | 75,3 | 130 | 151 | 199 | 412 | ||||||

| TF32 | 3/4" | 60°, 90°, 120°, 150°, 170° | - | 95,7 | 166 | 191 | 253 | 524 | ||||||

| TF40 | 1" | 60°, 90°, 120°, 150°, 170° | - | 153 | 265 | 306 | 405 | 838 | ||||||

| TF48 | 1" | 60°, 90°, 120°, 150°, 170° | - | 216 | 374 | 432 | 571 | 1180 | ||||||

| TF56 | 1 1/2" | 60°, 90°, 120°, 150°, 170° | - | 294 | 509 | 588 | 778 | 1610 | ||||||

| TF64 | 1 1/2" | 60°, 90°, 120°, 150°, 170° | - | 385 | 667 | 770 | 1020 | 2110 | ||||||

| TF72 | 1 1/2" | 60°, 90°, 120°, 150°, 170° | - | 438 | 759 | 876 | 1160 | 2400 | ||||||

| TF88 | 2" | 60°, 90°, 120°, 150°, 170° | - | 639 | 1110 | 1280 | 1690 | 3500 | ||||||

| TF96 | 2" | 60°, 90°, 120°, 150°, 170° | - | 806 | 1400 | 1610 | 2130 | 4410 | ||||||

| TF112 | 3" | 60°, 90°, 120°, 150°, 170° | - | 1170 | 2030 | 2340 | 3100 | 6410 | ||||||

| TF128 | 3" | 60°, 90°, 120°, 150°, 170° | - | 1540 | 2670 | 3080 | 4070 | 8430 | ||||||

| TF160 | 4" | 60°, 90°, 120° | - | 2390 | 4140 | 4780 | 6320 | 13100 | ||||||

Choose the right spray nozzle for an optimised spray process

Each type of nozzle has a specific flow rate, spray pattern and droplet size. To optimise the spray process, it is important to understand how different parameters affect the choice of spray nozzle and type of solution.

The Knowledge base contains information about spray pattern, droplet size, flow rate/pressure, spray coverage, materials, etc. The 'Materials' section of the Knowledge base lists the most commonly requested materials and maximum temperature of the material.

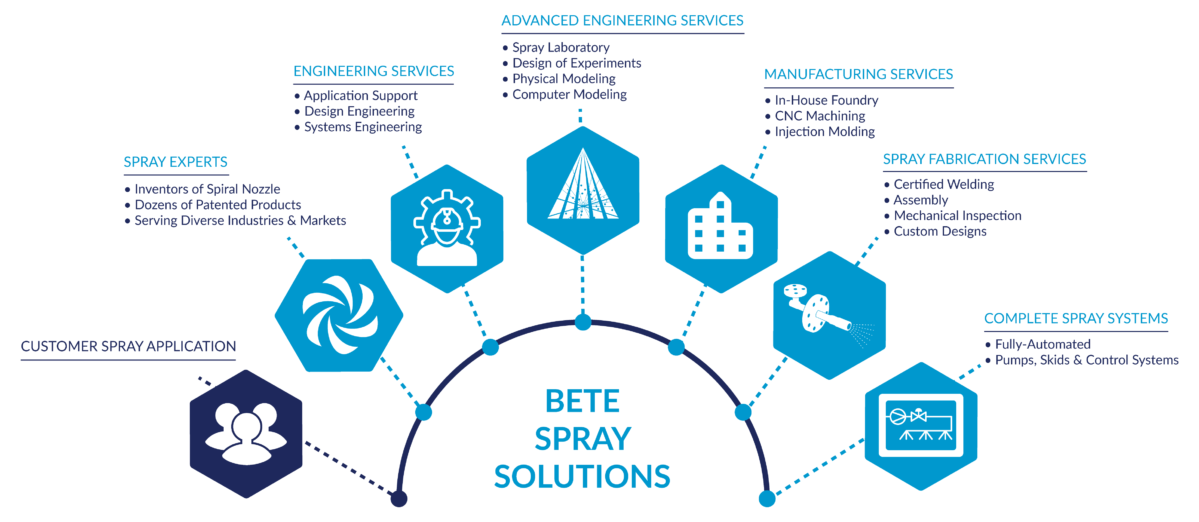

Our main supplier is BETE, a leading manufacturer of spray nozzles and spray systems with more than 70 years of experience in spray processes and a product range including over 20,000 components.

BETE's spray technology is used worldwide to optimise processes in many different industries, including the energy sector, chemical and petrochemical industry, food industry and offshore.

Some of BETE's certifications include ISO 9001:2015, ATEX and FM Approval.

BETE Performance Spray Engineering

BETE offers test facilities, CFD modelling, and advanced technical support. To ensure high quality and reliable deliveries, BETE's manufacturing is largely based 'in-house' with its own foundry, CNC machining, assembly and quality control.

BETE Certifications & Approvals

Click the button below for a full list of BETE's certifications. It is also possible to download some certificates.

Our customer promise

Right solution, technical expertise and commitment is what you can expect from us as your partner or supplier.

Support & service

We offer the support you need to optimise your process, minimise risk and achieve a sustainable solution.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.