Orbitor Hi Cap - Tank cleaning machine

HydroWhirl® Orbitor is a tank cleaning machine with a high impact, effective spray and is suitable for tanks and vessels up to Ø 40 m.

Designed with minimum moving parts to ensure extended operating life, reduced down-time and easy on-site maintenance.

- Product information

- Technical data

- Documentation & videos

- General info Tank cleaning

- Supplier information

- Certifications

- Send saved products to yourself, or as a quote request to Hansa

Design features

- Suitable for cleaning tanks and vessels up to Ø 40 m

- High impact spray

- Efficient wash cycle

- Compact design

- Low maintenance and extended operating life

- Self-cleaning and self-lubricating

- Easy on-site maintenance, see 'BETE HydroWhirl Orbitor Instruction and Maintenance Manual' under the Documentation & Videos tab.

- ATEX optional

| Spray angle | 360° (180° if necessary) |

|---|---|

| Spray pattern | See Datasheet |

| Flow rate | 80 - 600 l/min |

| Standard material - Body & Cap Nut | 316L |

| Connection | 1", 1 1/2" BSP/NPT |

| Dimensions | See Datasheet |

| Max temperature | See Datasheet |

Flow rates, spray angles & connections

For more information regarding flow rate, throw length and cleaning cycle duration, see Datasheet under the tab 'Documentation & videos'.

| Flow rate (l/min) @ Differential pressure (bar), Density (1 SG) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Connection | Spray angle | 3 bar | 4 bar | 5 bar | 6 bar | 8 bar | 10 bar | ||||||

| HWO 2x6.0 | 1 1/2" | 360° | 80,0 | 91,7 | 108 | 122 | 140 | 157 | ||||||

| HWO 2x7.0 | 1 1/2" | 360° | 93,3 | 117 | 137 | 153 | 182 | 200 | ||||||

| HWO 2x8.0 | 1 1/2" | 360° | 117 | 150 | 172 | 190 | 213 | 232 | ||||||

| HWO 2x10.0 | 1 1/2" | 360° | 217 | 255 | 290 | 320 | 368 | 405 | ||||||

| HWO 2x12.5 | 1 1/2" | 360° | 330 | 383 | 433 | 473 | 547 | 600 | ||||||

| HWO 4x4.2 | 1", 1 1/2" | 360° | 80,0 | 100 | 115 | 127 | 147 | 157 | ||||||

| HWO 4x5.0 | 1", 1 1/2" | 360° | 112 | 137 | 155 | 173 | 195 | 207 | ||||||

| HWO 4x6.0 | 1 1/2" | 360° | 138 | 170 | 200 | 220 | 257 | 282 | ||||||

| HWO 4x7.0 | 1 1/2" | 360° | 217 | 252 | 283 | 310 | 350 | 380 | ||||||

| HWO 4x8.0 | 1 1/2" | 360° | 250 | 293 | 333 | 367 | 418 | 458 | ||||||

Choose the right product for optimised tank cleaning

Choosing the right product is mainly determined by the type of media the tank contains and the diameter of the tank. In addition, there are a number of other factors to consider in order to achieve an effective tank cleaning process.

The Knowledge base provides more information about the difference between various types of tank cleaning nozzles, tank or vessel design, purpose of the tank cleaning process, importance of the washing liquid, etc.

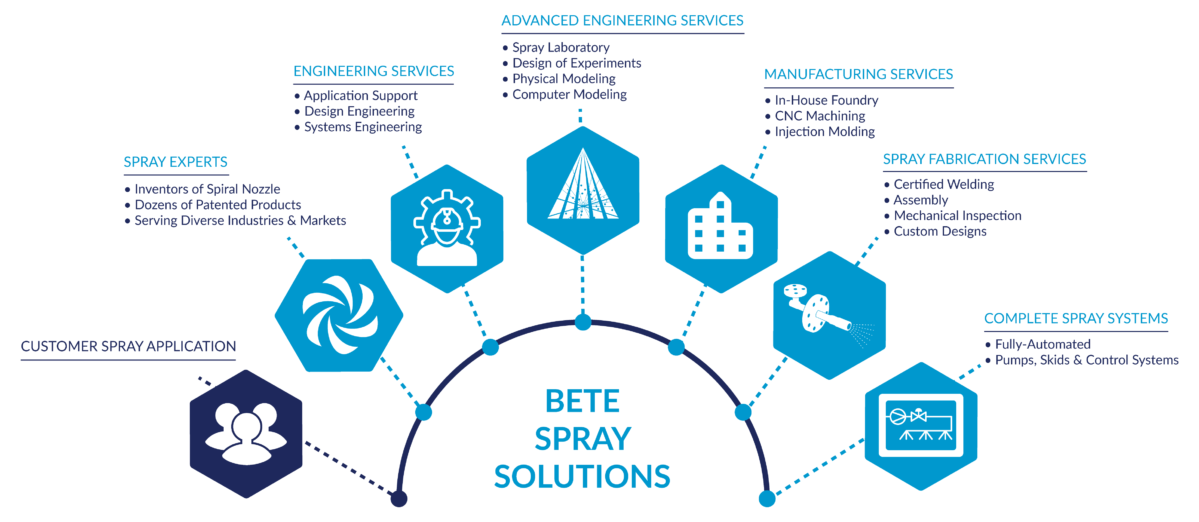

Our main supplier is BETE, a leading manufacturer of spray nozzles and spray systems with more than 70 years of experience in spray processes and a product range including over 20,000 components.

BETE's spray technology is used worldwide to optimise processes in many different industries, including the energy sector, chemical and petrochemical industry, food industry and offshore.

Some of BETE's certifications include ISO 9001:2015, ATEX and FM Approval.

BETE Performance Spray Engineering

BETE offers test facilities, CFD modelling, and advanced technical support. To ensure high quality and reliable deliveries, BETE's manufacturing is largely based 'in-house' with its own foundry, CNC machining, assembly and quality control.

BETE Certifications & Approvals

Click the button below for a full list of BETE's certifications. It is also possible to download some certificates.

Our customer promise

Right solution, technical expertise and commitment is what you can expect from us as your partner or supplier.

Support & service

We offer the support you need to optimise your process, minimise risk and achieve a sustainable solution.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.